Applicable industries: automotive, bicycle, medical, electronic, motor, fitness equipment, mechanical and Airsoft fields.

Manufacture

CORE VALUE

- EFFICIENCY

- QUALITY

- SPECIALIZATION

Distribution

ADVANCED CNC MACHINES & DIE-CASTING MACHINES

High rigidity, stability, precision and efficiency.

Capable of customizing machine configuration according to customers’ unique requirements.

Tapping Center

Vertical Machining Center

Horizontal Machining Center

Double Column Machining Center

Turning Lathe Machine

Die-Casting Machine

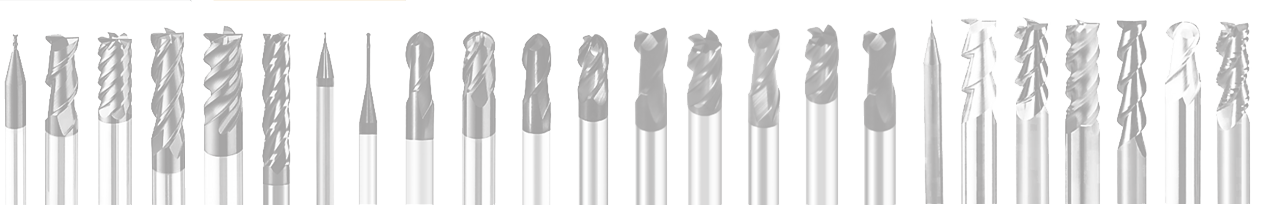

PRECISION CNC END MILLS

High rigidity & Wear resistance

Materials imported from Germany & Manufactured by advanced German CNC machine

Capable of customizing tool according to customers’ unique requirements